Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

APPLICATION INDUSTRY

APPLI

INDUSTRY

PHOTOVOLTAIC INVERTER HEAT DISSIPATION

Solution to Heat Dissipation of Photovoltaic Inverter(210KW)

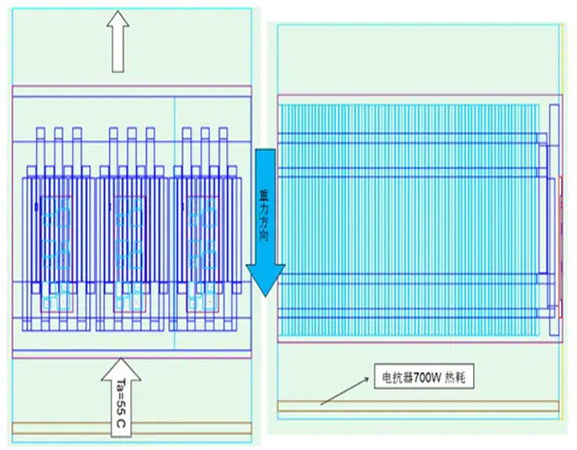

Simulation model and parameter schematic diagram (1):

ambient temperature:55⁰C,Reactor Heat Consumption:700W

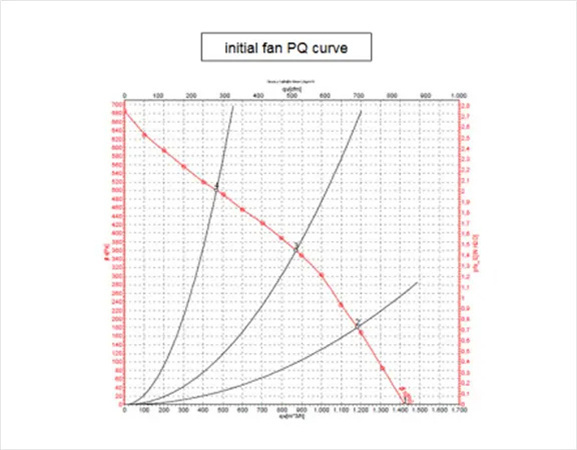

Assuming the system impedance is 80Pa, the curve of the fan passing through the radiator is as follows:

Assuming the system impedance is 80Pa, the curve of the fan passing through the radiator is as follows:

The left figure shows the internal structure of Infineon and the schematic diagram of heating elements.

Diode:59W; IGBT:124.5W; Total:1100WW;

Assuming that the heat conducting medium is:0.15mm Thick,K=3W/m*K.

Assuming the system impedance is 80Pa, the curve of the fan passing through the radiator is as follows:

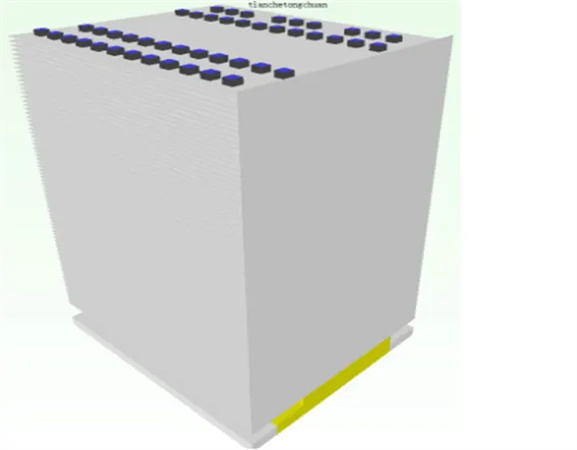

Heatsink parameters:

Size:W236*L200*H304mm

Fin :

Thick:0.6mm

Pitch between teeth:3.0mm

Number of teeth:77fins

Heat pipe parameters:

D8 Sintered tube or fibre tube;

Use 24pcs U heat pipe (one layer layout) and type 48 PCs L heat pipe (two layers layout);

Welding with 4258 low temperature solder paste;

Substrate: AL Plate + Copper Plate (IGBT Heat Source Area)

Compared with two-layer heat pipe, one-layer heat pipe has lower cost and higher heat dissipation efficiency.

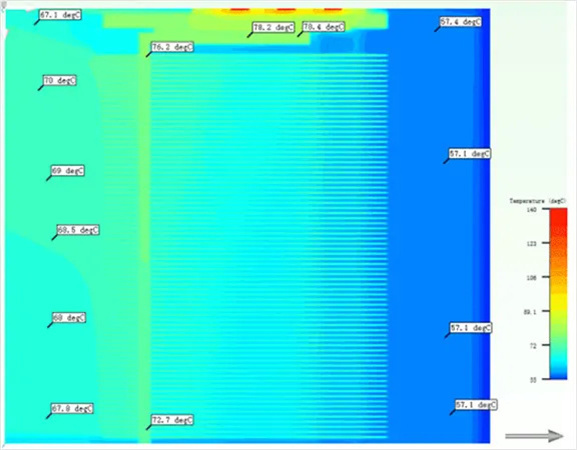

Simulation sketch of pressure diffusion degree of section in module:

Simulation sketch of pressure diffusion degree of section in module:

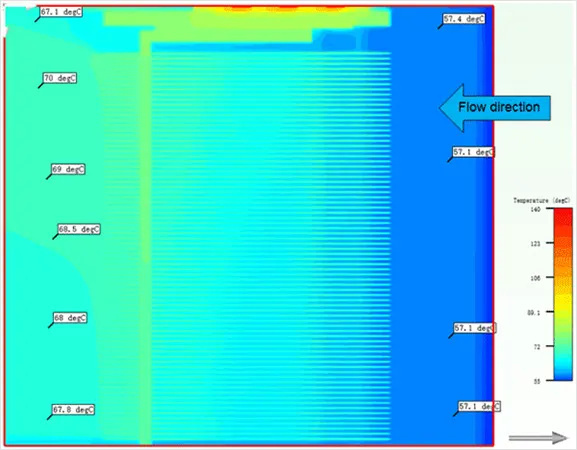

Temperature Diffusion Simulation Diagram of Section in Module:

Temperature diffusion simulation sketch of top heat pipe:

The temperature difference between the two ends of the heat pipe is 5.7 degrees, which meets the actual heat pipe standard.

Temperature diffusion simulation sketch of bottom heat pipe:

The temperature difference between the two ends of the heat pipe is 9 C, slightly higher than the actual, and the actual performance of the heat pipe will be better than the analysis setting.

Temperature Diffusion of Heat Pipe at the Bottom of Radiator:

The actual air intake temperature of the radiator is ~57.1 C, and the maximum temperature of the radiator bottom is 85.1 C, Theoretical analysis of temperature rise of 28℃

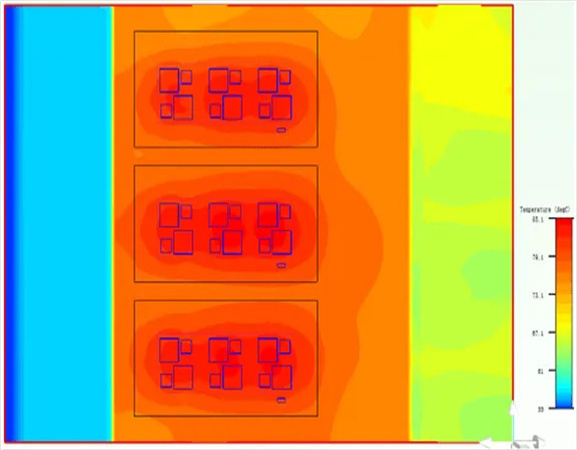

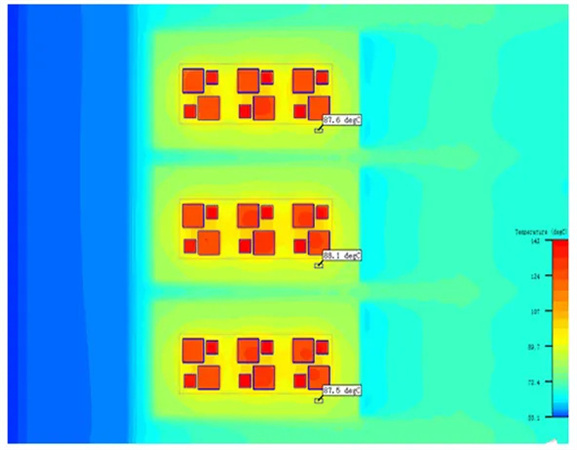

NTC Temperature Diffusion Simulation Diagram of Module:

The temperature difference between the two ends of the heat pipe is 9 C, which is slightly higher than the actual situation. The actual performance of the heat pipe will be better than the analysis setting.

Diagram of Fan Action Point:

Summary of simulation data of photovoltaic inverter cooling scheme:

| Solution | Ta | Power | H.S Tb max |

H.S DT |

HTC1 | HTC2 | HTC3 | Fan working point |

|---|---|---|---|---|---|---|---|---|

| Al base+ copper block |

55 | IGBT/3pcs 1100W/each Reactor 700W |

85.1 | 28 | 87.6 | 88.1 | 87.5 | 1127.5 m^3/Hr 215Pa |

Assuming that the air temperature of the system is 55_C and 57.1_C after entering the reactance, assuming the use of thermal conductive medium 0.15mm,K=3W/m*K)