Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

PRODUCTS

Die Casting

Die-casting parts are a type of pressure casting parts that use a pressure casting mechanical die-casting machine equipped with a casting mold to pour molten copper, zinc, aluminum, or aluminum alloys into the feeding port of the die-casting machine.

Classification:

Die Casting

Key words:

Die Casting

Contact us

Product description

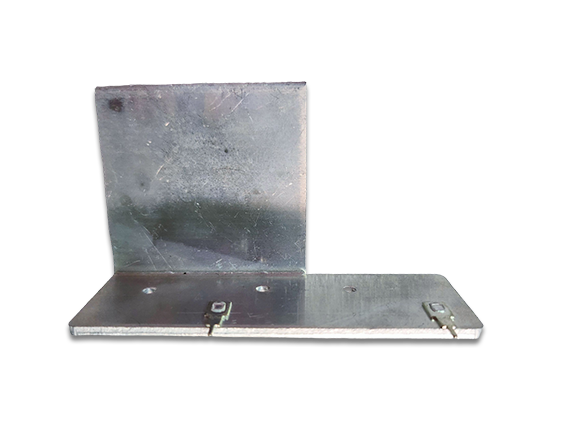

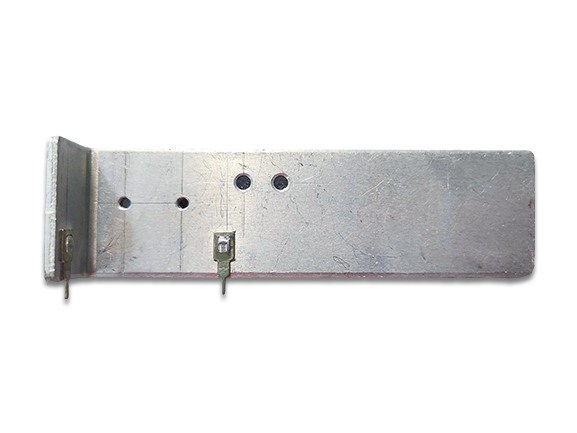

Die-casting parts are a type of pressure casting parts that use a pressure casting mechanical die-casting machine equipped with a casting mold to pour molten copper, zinc, aluminum, or aluminum alloys into the feeding port of the die-casting machine. After being die-cast by the die-casting machine, copper, zinc, aluminum, or aluminum alloy parts with the shape and size limited by the mold are cast. Such parts are usually called die-casting parts. Die-casting parts have different names in different places, such as die-casting parts, pressure castings, die-casting parts, die-casting aluminum, die-casting zinc parts, die-casting copper parts, copper die-casting parts, zinc die-casting parts, aluminum die-casting parts, aluminum die-casting alloy castings, aluminum alloy die-casting parts, etc.

Die-casting parts can be manufactured as die-casting automotive parts, die-casting automotive engine parts, die-casting air conditioning parts, die-casting gasoline engine cylinder heads, die-casting valve rocker arms, die-casting valve supports, die-casting power parts, die-casting motor end caps, die-casting shells, die-casting pump shells, die-casting building parts, die-casting decorative parts, die-casting guardrail parts, die-casting wheels, and other parts. With the continuous improvement of the development level of the domestic manufacturing equipment industry, The equipment level of die-casting machines has also significantly improved, and the types of parts that can be manufactured are constantly expanding. The accuracy and complexity of the parts produced by die-casting have also been greatly improved. We believe that in the near future, die-casting parts will better serve our production and life!

Die cast aluminum alloy

Aluminum alloy has low density but relatively high strength, approaching or surpassing high-quality steel, good plasticity, and can be processed into various profiles. It has excellent conductivity, thermal conductivity, and corrosion resistance, and is widely used in industry, with a usage only second to that of steel. The specific weight of aluminum alloy is only about one-third of that of iron, so its use is very important in various industries, especially in the lightweight process of aircraft, ships, automobiles, electronic instruments, etc. It plays an indispensable role.

Commonly used are the Al Si Cu system, while common ones include ADC12 (A383), ADC10 (A380), etc. In addition, there are also Al Si, Al Si Mg, and Al Mg systems. Currently known as aluminum titanium alloy, it is improved by adding titanium metal to the above materials, which can significantly improve the mechanical properties of the product.

Prev

Next

Prev

Next