language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

APPLICATION INDUSTRY

APPLI

INDUSTRY

ELECTRIC VEHICLE CONTROLLER

Solution to Heat Dissipation of Electric Vehicle Controller:

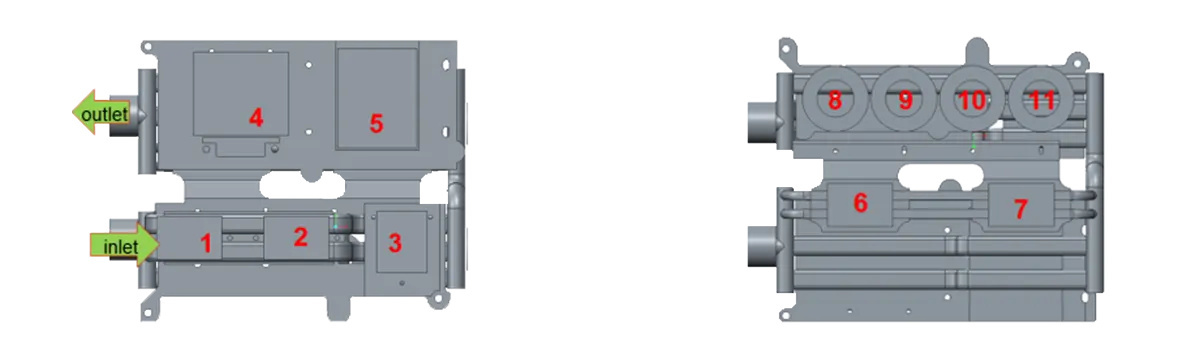

The back of the heat sink plate is designed to fully contact with the thermal elements, which can improve the heat dissipation efficiency of the heat sink area.

Heat Consumption and Contact Area of Power Devices:

| Component (Number) | contact area(mm²) | Power(w) |

| 1 Rectifer Module | 1192.99 | 121 |

| 2 IGBT Module | 1192.99 | 316 |

| 3 Resonance lnductor | 1299.62 | 18 |

| 4 Output lnductor | 3363.57 | 16 |

| 5 Transformer | 3363.57 | 70 |

| 6 PFC Madule | 1192.99 | 50 |

| 7 PFC Module | 1192.99 | 50 |

| 8-11 PFC Choke(Each Group) | 1002.05/Group | 24/Group |

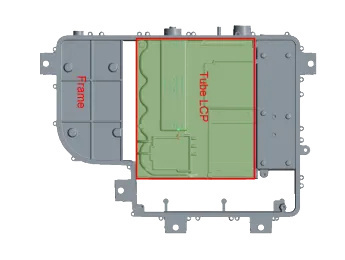

The grid schematic diagram of water-cooled heat sink plate and heat sink tube:

The whole schematic diagram of the radiator of the electric vehicle controller:

(Total weight:2.55Kg,Frame:1.7Kg,Cold plate:0.85Kg)

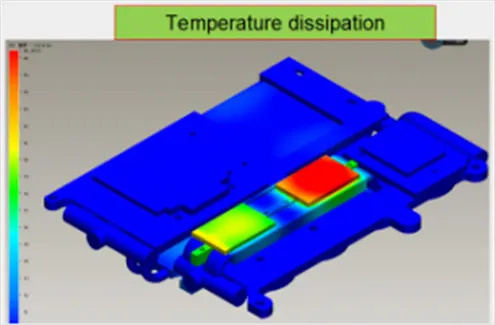

The heat dissipation simulation effect sketch of the electric vehicle controller 1:

(When the water cooling velocity is:5L/min ,Initial temperature of water:25 ⁰C,Water pressure is:10485Pa,The maximum simulation temperature of water-cooled plate is:46.5 ⁰C)

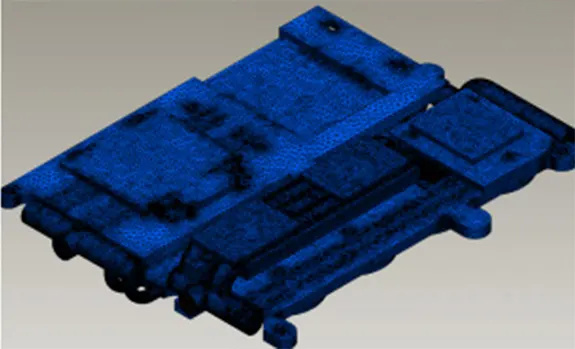

The heat dissipation simulation effect sketch of the electric vehicle controller 2: