language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

APPLICATION INDUSTRY

APPLI

INDUSTRY

WIND POWER CONVERTERS DISSIPATE HEAT

WIND ENERGY CONVERTER COOLING SOLUTION(DCDC 3000W transient solution)

Converter simulation model and related parameters:

Converter simulation model and related parameters:

The infineon internal structure diagram and heating element diagram:

diode:34W; IGBT:91W; total 1500W;

Assuming heat-conducting medium:

7762 thermal grease, thickness is 0.2mm, K=4W/m*K.

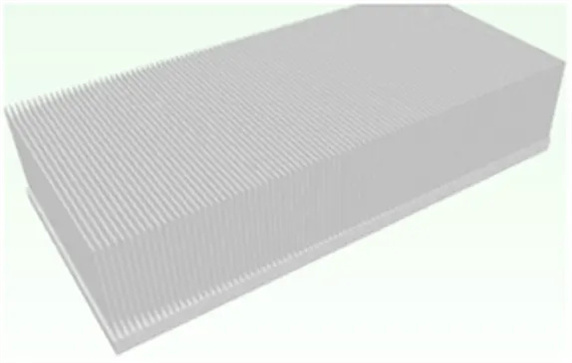

Heatsinkparameter:

Substratesize:462*220*15mm;

Finthickness:1.5mm;

Finqty:92fins;

Finheight:87mm;

Material:AL1060;

Process:Skived;

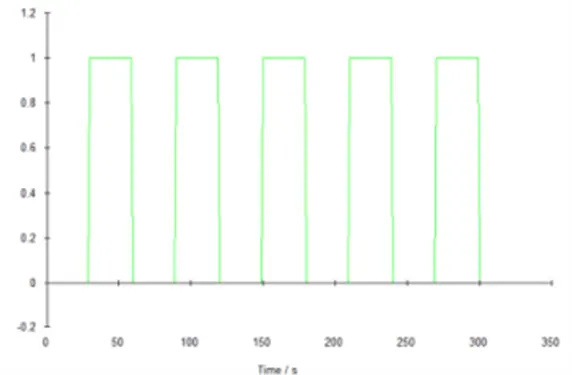

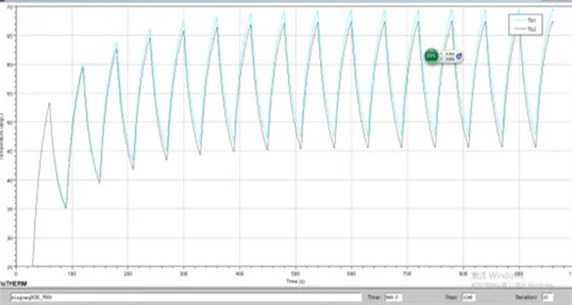

Runsfor16cycles,atotalof960s。

Heat sink design simulation model and related parameters

Workingstatusofheatsource:

0-29s:0%;

29s-30s:from0%to100%;

30s-59s:100%;

59s-60s:from100%to0%;

Run60scircularlyatacycle.

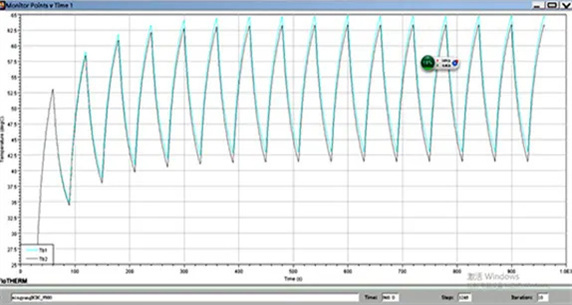

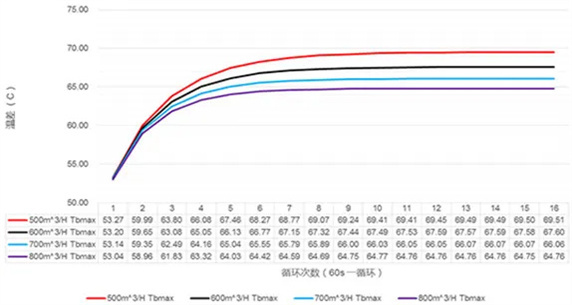

The diagram of Tb temperature over time: ( airflow:500m^3/H)

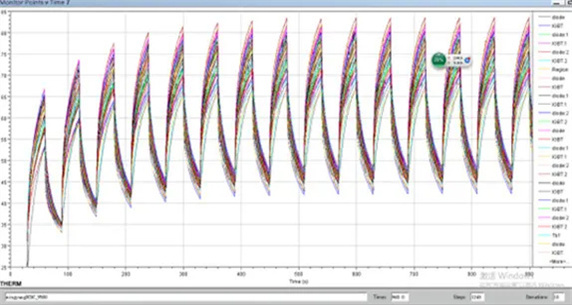

The change diagram of surface temperature over time of IGBT core components:

Airflow: 500m^3/H, IGBT node temperature = core element surface temperature + core element power * core element

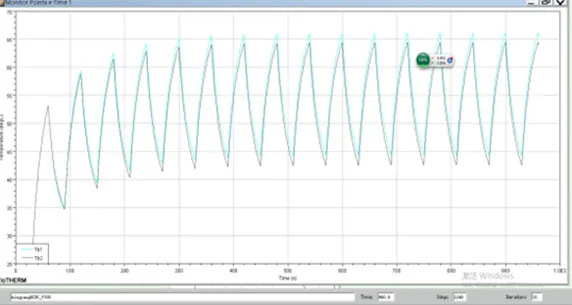

The diagram of Tb temperature over time: ( airflow:600m^3/H)

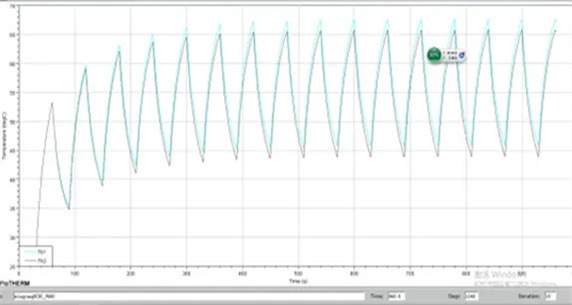

The diagram of Tb temperature over time: ( airflow:700m^3/H)

The diagram of Tb temperature over time: ( airflow:800m^3/H)

The time cycling variation simulation results of highest surface temperature of heat source bottom radiator:

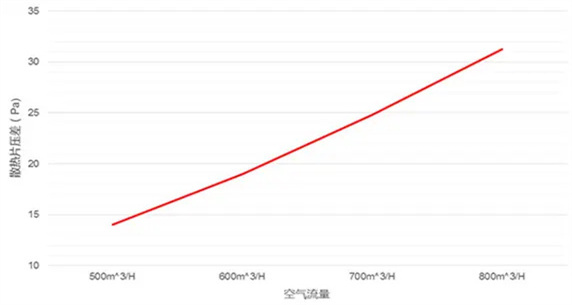

Simulation results of heat sink pressure loss and flow: