Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

PRODUCTS

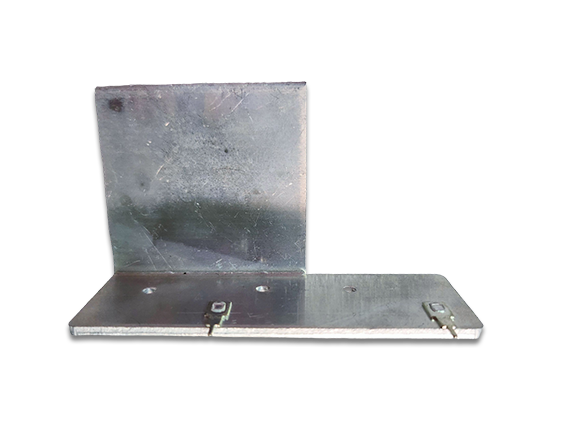

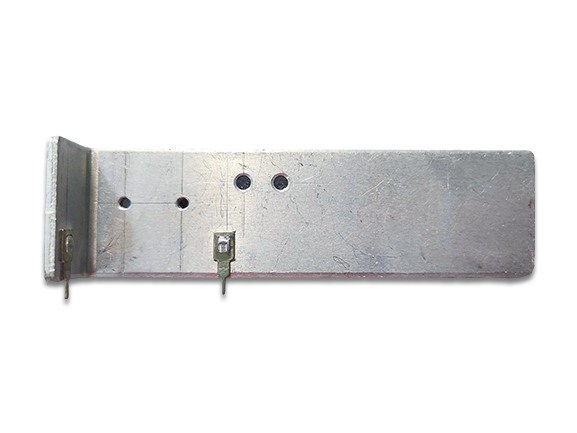

VC Heat pipe heat sink

Material: VC soaking plate is the abbreviation of VaporChamber, also known as vacuum chamber soaking plate heat dissipation technology. In the early stages of mobile phone cooling, graphite was usually used as the main material and can be referred to as the first generation of cooling.

Classification:

VC Heat pipe heat sink

Key words:

VC Heat pipe heat sink

Contact us

Product description

Material: VC soaking plate is the abbreviation of VaporChamber, also known as vacuum chamber soaking plate heat dissipation technology. In the early stages of mobile phone cooling, graphite was usually used as the main material and can be referred to as the first generation of cooling. Then, copper tube liquid cooling is the second generation heat dissipation technology VC, and the third generation heat dissipation technology is the soaking plate. VC liquid cooling can be used as a dimensional improvement technology for copper tube liquid cooling. Although both are based on the principle of gas-liquid phase, the difference lies in the fact that the heat pipe has only one direction, with a "linear" effective thermal conductivity. VC is equivalent to a "line to surface" dimensionality that can better remove heat from all directions.

VC in the industry is generally referred to as VC heat sink, VC uniform temperature plate, VC uniform heat plate, flat heat pipe, etc. Widely used in mobile phones, computers, servers, graphics cards, etc., for heat dissipation. Most of the existing heat dissipation panels are made of copper substrate for easy welding, and the production method includes sintering structure.

Product name: VC soaking plate

Material: c1020, C5190, SUS316L, stainless steel, etc.

Thickness (metric): 0.08mm, 0.2mm, 0.03mm, 0.05mm, 0.3mm, etc.

Product features: Various complex shapes can be etched and processed, and the product has no burrs.

Product price: determined based on material quality, precision requirements, mass production quantity, thickness, and other factors.

Etching capacity: capable of mass production, with a daily production capacity of over 2000 square meters.