Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

PRODUCTS

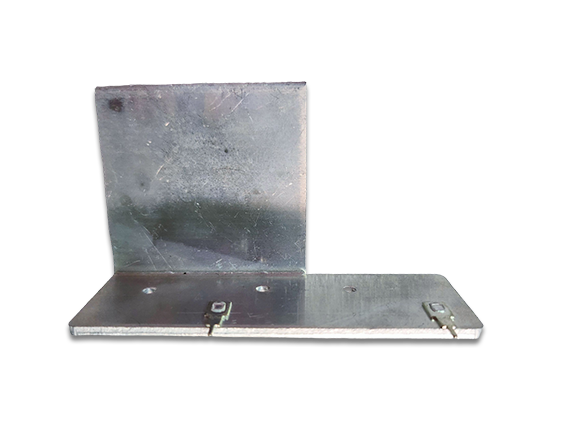

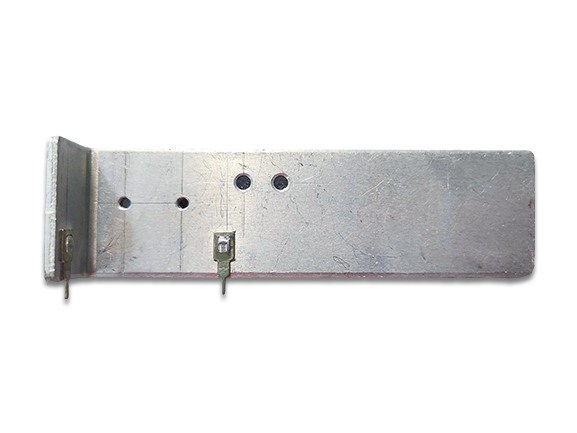

CNC machining parts

(1) The CNC numerical control process should consider the processability of the processed parts, determine the clamping and positioning of the processed parts, select cutting tools, formulate process routes, cutting methods, and process parameters, which can be simplified in conventional processes.

Classification:

CNC machining parts

Key words:

CNC machining parts

Contact us

Product description

(1) The CNC numerical control process should consider the processability of the processed parts, determine the clamping and positioning of the processed parts, select cutting tools, formulate process routes, cutting methods, and process parameters, which can be simplified in conventional processes.

(2) CNC numerical control process design is mainly used to guide CNC numerical control programming. Our company combines the responsibilities of CNC numerical control technicians and programmers into one, and the programmer is responsible for the CNC numerical control machining process of the whole set of molds, which improves work efficiency.

(3) The automation level of CNC machining is high, and there are many influencing factors in CNC machining. Quality and safety are crucial and must be guaranteed

(4) The preparation of CNC numerical control technology should have strict organization. The CNC numerical control process is complex and has many influencing factors. It requires careful consideration of the entire process of CNC machining, and good organization is necessary to program the CNC numerical control process. In addition, the high degree of automation in CNC machining results in low adaptive ability. Once problems occur, it is difficult for workers to correct them on site, which can cause processing defects in light cases and safety accidents in severe cases. Therefore, it is necessary to design the CNC numerical control process in a systematic manner in advance.

(5) CNC technology has good inheritance. All CNC numerical processes that have been proven to be good in production can be made into templates and saved as archives, which can be used for processing similar date pieces in the future to save time and ensure quality.

Huafu Hardware Products Co., Ltd. has over ten years of CNC processing experience and has a deep accumulation in specific projects such as precision machining of various metals such as aluminum alloy parts, machining of automation equipment parts, and so on

CNC (Computer Numerical Control) machining is a process that uses computer-controlled machines to manufacture parts with precision and accuracy. The parts are created by cutting, drilling, grinding, and shaping materials such as metals, plastics, and wood using a variety of tools and equipment.

The first step in CNC machining parts is to design the part using software programs such as AutoCAD or SolidWorks. The design includes the shape, size, and features of the part. Once the design is complete, it is sent to a CNC machine for programming.

During programming, the machine is set up to follow the instructions in the design file. This includes determining where to cut and how deep to drill for holes. The machine then begins the manufacturing process.

The CNC machine moves around the material being used, cutting and drilling it into the desired shape. The machine uses sensors and cameras to ensure that the parts are accurate and precise. After the parts are finished, they are removed from the machine and inspected for quality assurance purposes.

In summary, CNC machining parts involves designing the part, programming the machine, and using it to manufacture accurate and precise parts with minimal waste.

Prev

Next

Prev

Next