Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

APPLICATION INDUSTRY

APPLI

INDUSTRY

THE POWER BATTERY PACK DISSIPATES HEAT

Power batteries are the batteries that provide power for machines as power sources, generally referring to the batteries that provide power for new energy vehicles such as electric vehicles, electric trains and so on. New energy vehicles refer to those vehicles with advanced technology in power control and drive, which are formed by using unconventional vehicle fuel as power source and integrating advanced technology in vehicle power control and drive. New energy vehicles are regarded as promising because of their energy-saving and environmental protection characteristics and are strongly supported by national policies to implement the State Council's policy on fostering strategic emerging products. Deployment and requirements for energy conservation and emission reduction should be strengthened. The central government should allocate special funds to support the pilot project of subsidies for private purchases of new energy vehicles.

New energy vehicles are mainly composed of battery drive system, motor system, electronic control system and assembly. Among them, motor, electronic control and assembly are basically the same as traditional automobiles. The biggest difference lies in the difference of power sources. Power battery pack is an important power source for new energy automobiles. The majority of new energy automobile enterprises have increased their research and development on power battery pack to solve the technical bottleneck of high cost, weak battery endurance and low charging speed of power battery pack. In addition, technical cooperation with heat dissipation enterprises such as thermal energy is launched to improve the performance of power battery packs.

Solution to Water Cooling and Heat Dissipation of Power Battery Package:

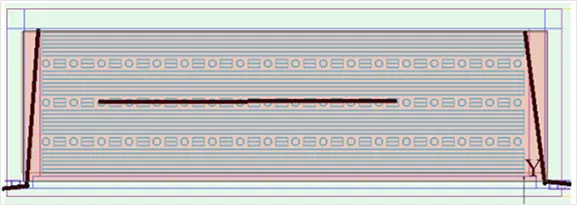

Schematic diagram of simulation model for power battery pack and water cooling plate:

The heat dissipation scheme is demonstrated by the deployment and placement of five water-cooled boards, and the total power is obtained 1400W.

(1)cold plate A: 476* 134.4,souce size:179.2*134.4;

(2)Light red is the heating area.,136.5W/each,total 273W;

(3)The diagram shows the distribution of water flow,Lower cover plate 3.0mm Thick,Upper cover plate 4.0mm Thick,Middle fin 3.0mm fin Thickness 1.0, Spacing 3.0mm, fin length 164mm, totoal 22fins;

(4)Intermediate cylinder(D10)Strengthen the position of the structure (after screw is fixed, seal).

(1)cold plate B: 476* 57.4 souce size:177*44.3;

(2)Light red is the heating area.,44.5W/each,total 89W;

(3)The diagram shows the distribution of water flow,Lower cover plate 3.0mm Thick,Upper cover plate 4.0mm Thick,Middle fin 3.0mm fin Thickness 1.0, Spacing 3.0mm, fin length 165mm, totoal 9fins.

(1)cold plate C:670*240 souce size:663*180;

(2)Light red is the heating area,total 676W;

(3)The diagram shows the distribution of water flow,Lower cover plate 3.0mm Thick,Upper cover plate4.0mm Thick,Middle fin 3.0mm fin Thickness 1.0,Spacing 4.0mm, fin length 610mm, 7*4=28fins.

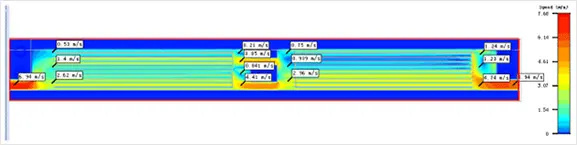

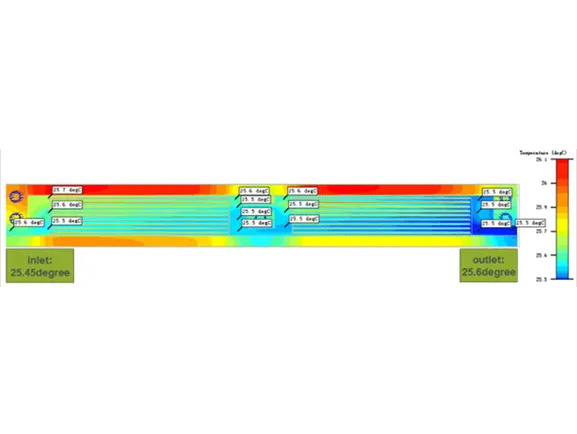

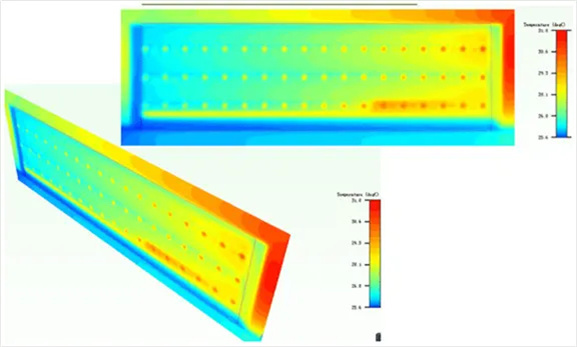

Power Battery Pack #1 Schematic diagram of simulation results of heat dissipation of water-cooled plate:

(1)Indicating the Velocity Diffusion Degree of Section in Water-cooled Plate

(2)Indicating the Velocity Diffusion Degree of Section in Water-cooled Plate

(3)Indicating the Velocity Diffusion Degree of Section in Water-cooled Plate

(4)Temperature diffusion simulation sketch of water-cooled plate

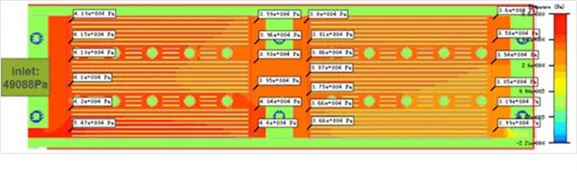

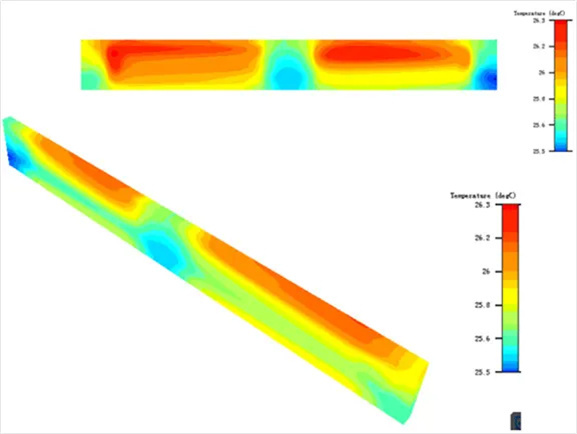

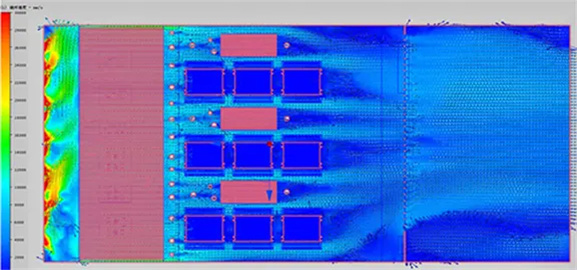

Power Battery Pack #2 Schematic diagram of simulation results of heat dissipation of water-cooled plate:

(1)Indicating the Velocity Diffusion Degree of Section in Water-cooled Plate

(2)Pressure Diffusion Degree Indication of Water-cooled Plate Medium Section

(1)Indicating the Velocity Diffusion Degree of Section in Water-cooled Plate

(2)Pressure Diffusion Degree Indication of Water-cooled Plate Medium Section

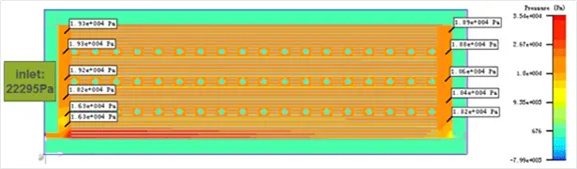

Power Battery Pack #3 Schematic diagram of simulation results of heat dissipation of water-cooled plate

(1)Indicating the Velocity Diffusion Degree of Section in Water-cooled Plate

(2)Pressure Diffusion Degree Indication of Water-cooled Plate Medium Section

(3)Temperature Diffusion Degree Indication of Water-cooled Plate Medium Section

(4)Pressure Diffusion Degree Indication of Water-cooled Plate Medium Section

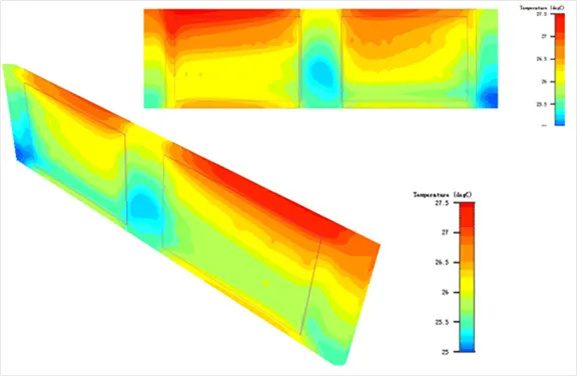

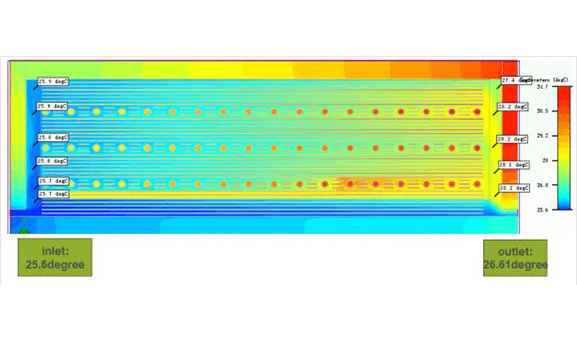

Power Battery Pack #4 Schematic diagram of simulation results of water-cooled plate heat dissipation (temperature diffusion degree)

Power Battery Pack #4 Schematic diagram of simulation results of water-cooled plate heat dissipation (temperature diffusion degree)

Summary of simulation data of heat dissipation solution for water cooling plate of power battery pack

(1)Cooling medium:50% Glycol 50% Water,Flow 10L/min,25?C;

(2)The outlet water temperature is in 27.3 degree,Water cooling temperature difference 2.3?C;

(3)Maximum temperature of heatsink 29.3?C;

(4)#1 Differential pressure 19200Pa,#2 Differential pressure 19700Pa,#3 Differential pressure 4300Pa;

(5)The overall pressure difference of the module is:19200*2+19700*2+4300=82100Pa